Engineering Excellence Since 2013

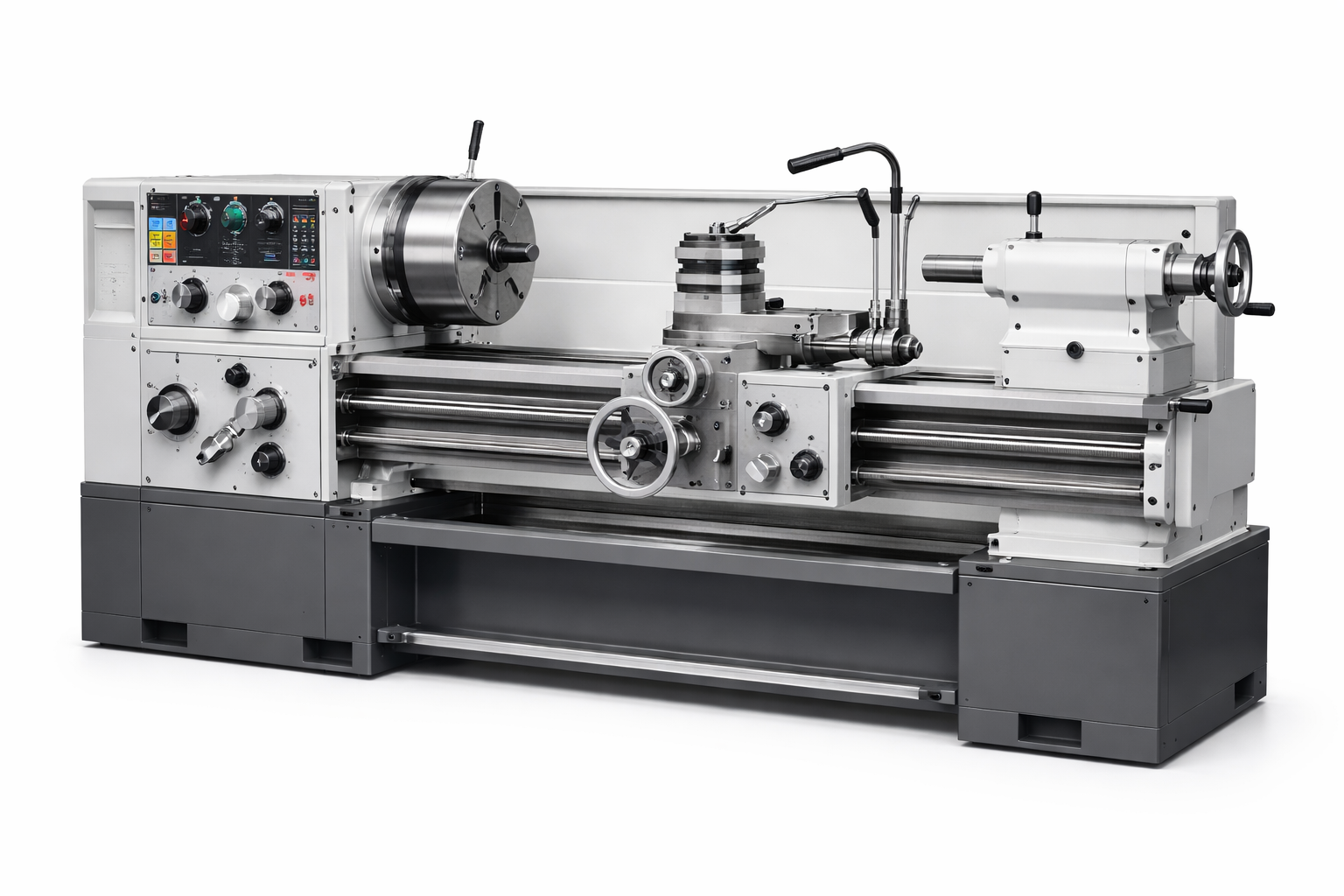

A Design & Engineering Company focused on providing innovative solutions to all types of industries

Founded in May 2013, Innovative Engineering Solutions has grown into a trusted name in precision engineering and custom manufacturing. Based in Chennai, India, we specialize in transforming complex engineering challenges into elegant, efficient solutions.

As an ISO 9001:2015 certified company, we maintain the highest standards of quality in every project we undertake. From concept design to final delivery, our team ensures precision, reliability, and innovation at every step.

ISO 9001:2015 Certified

Quality management at its finest

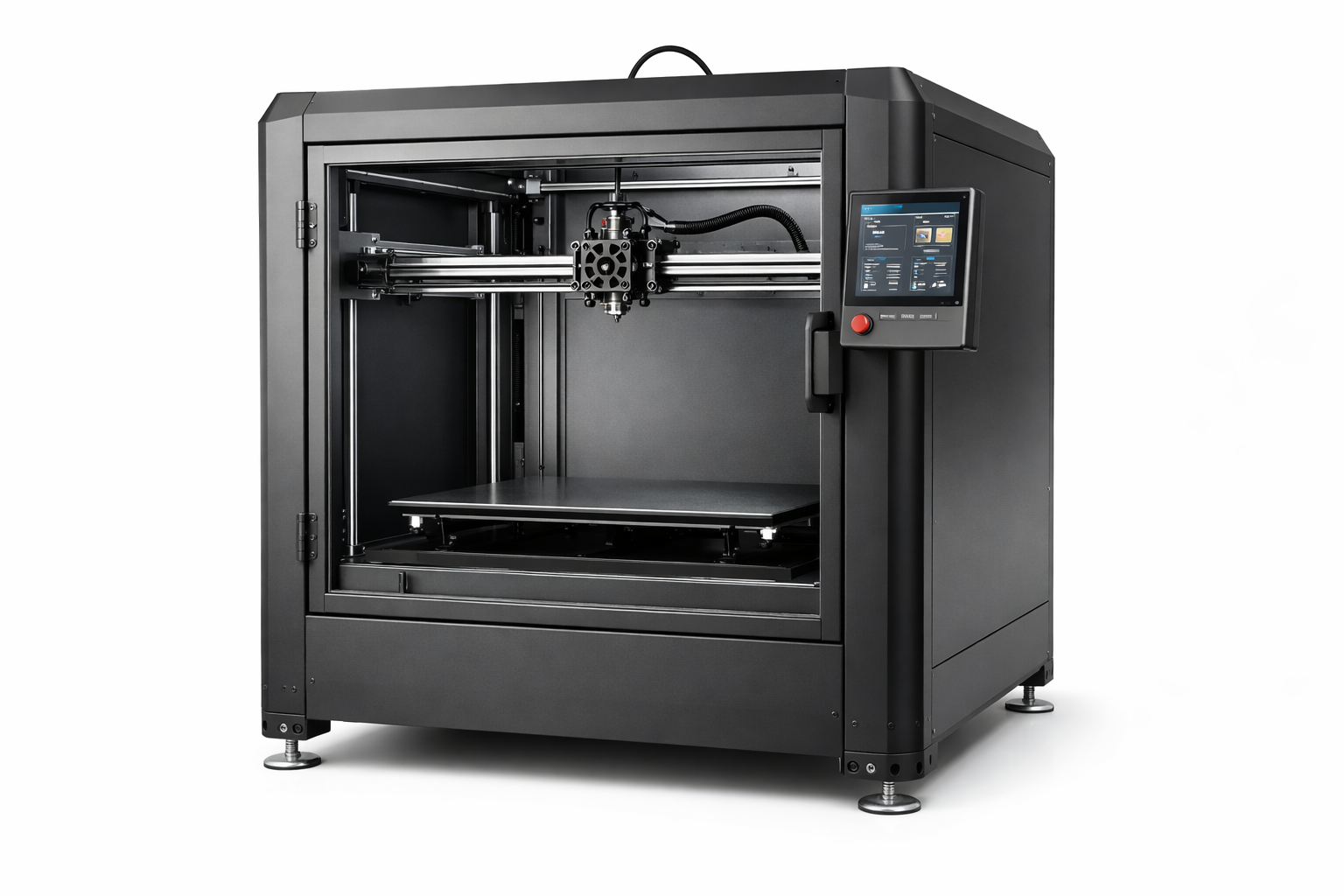

Product Development

From concept to reality

Expert Team

Skilled designers, fitters & operators